Dry Ice Blasting vs. Traditional Cleaning Methods

Industrial cleaning companies offer new methods every day, so when you work in an industry that needs specific hygiene, hygienic or particle removing standards, you want the most effective and most dependable form of cleaning possible. Blasting technologies have recently been around for some time, and among the most effective is dry glaciers blasting. Learn why dry out ice blasting is 1 of the best, safest and most effective methods of modern cleaning currently available.Just what Is Dry Ice Blasting?

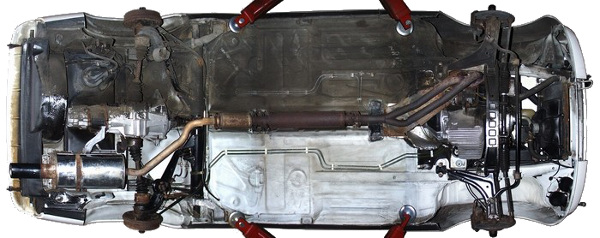

Dry ice blasting makes use of frozen carbon dioxide, a substance which is obviously found in our atmosphere and is kept at extremely cold temperatures of -78. 5°C/-109°F. When it is confronted with temperatures more comfortable than that, it instantly turns into a fuel vapor.In dry glaciers blast cleaning, dry glaciers units are widely-used to fireplace pellets the size of grain grains using compressed air at roughly the rate of sound. These allergens then skyrocket dirt, muck, grease and other heavy soiling as well as efficiently. Typically the process is easily as well as quite safe.

Non-Abrasive Dry Ice Boost Cleaning

CO2 blast cleaning carries several advantages over other varieties of commercial and professional cleaning. It is very similar to sandblasting, soda blasting or bead blasting, and simply as effective, but is far gentler to the actual surface. It carries a lesser amount of risk of scratches, riflard or scuffs, because it works on a completely different principle.When freezing cool dry ice pellets struck the surface to be cleaned, the extreme temperature ranges cause the contamination to become brittle and simply break away. Since the dry ice vaporizes on contact, the cleaning result is explosive but not abrasive. It lifts impurities away damaging the root surface, a process known as micro-thermal shocks. Typically the now-solid contaminants simply tumble away to be easily embroiled later!

No Corrosion or Shocks

When it comes to equipment, LASER blasting cleaning is even superior to water blasting, as water can create flash rusting which disturbs with paint and equipment repair. It also can produce electrical hazards which are no problem with dry glaciers.Eco-Friendly Solution

In evaluation to methods like solvent cleaning utilised by many commercial cleaning companies, CO2 cleaning is genuinely eco-friendly. Considering that carbon dioxide is a material that is found in nature, you’re not creating lots of waste at all. The process has even been approved by the EPA, FDA and USDA as eco-friendly. It is non-toxic, non-hazardous and even helps you to inhibit the development of molds and pathogens. This process is so safe it’s even used in food processing vegetation.Other Advantages

In addition, CO2 dry ice cleaning is so effective it has a wealth of other benefits including:- Fewer cleaning cycles

- Less downtime

- Nonflammable

- Nonconductive

- Safe for owner use

Interesting blog!! Thank you for sharing . Dry ice blasting is ideal for cleaning spaces like power plants and electrical equipment. It can be used to easily remove carbon build-ups, grime and contaminants.

ReplyDelete